The Importance of the Crankshaft on Engine Performance

The crankshaft on an engine is often described as the heart of the mechanical marvel that is an internal combustion engine. It plays a pivotal role in transforming the linear motion of the pistons into rotational motion, which ultimately powers the vehicle. Understanding the functionality, maintenance, and significance of the crankshaft is essential for anyone involved in the automotive industry, particularly in the fields of diesel engine parts and spare parts suppliers. This article delves into the intricacies of crankshafts, discussing their role in engine performance, maintenance best practices, and how they fit into the broader context of diesel engine functionality.

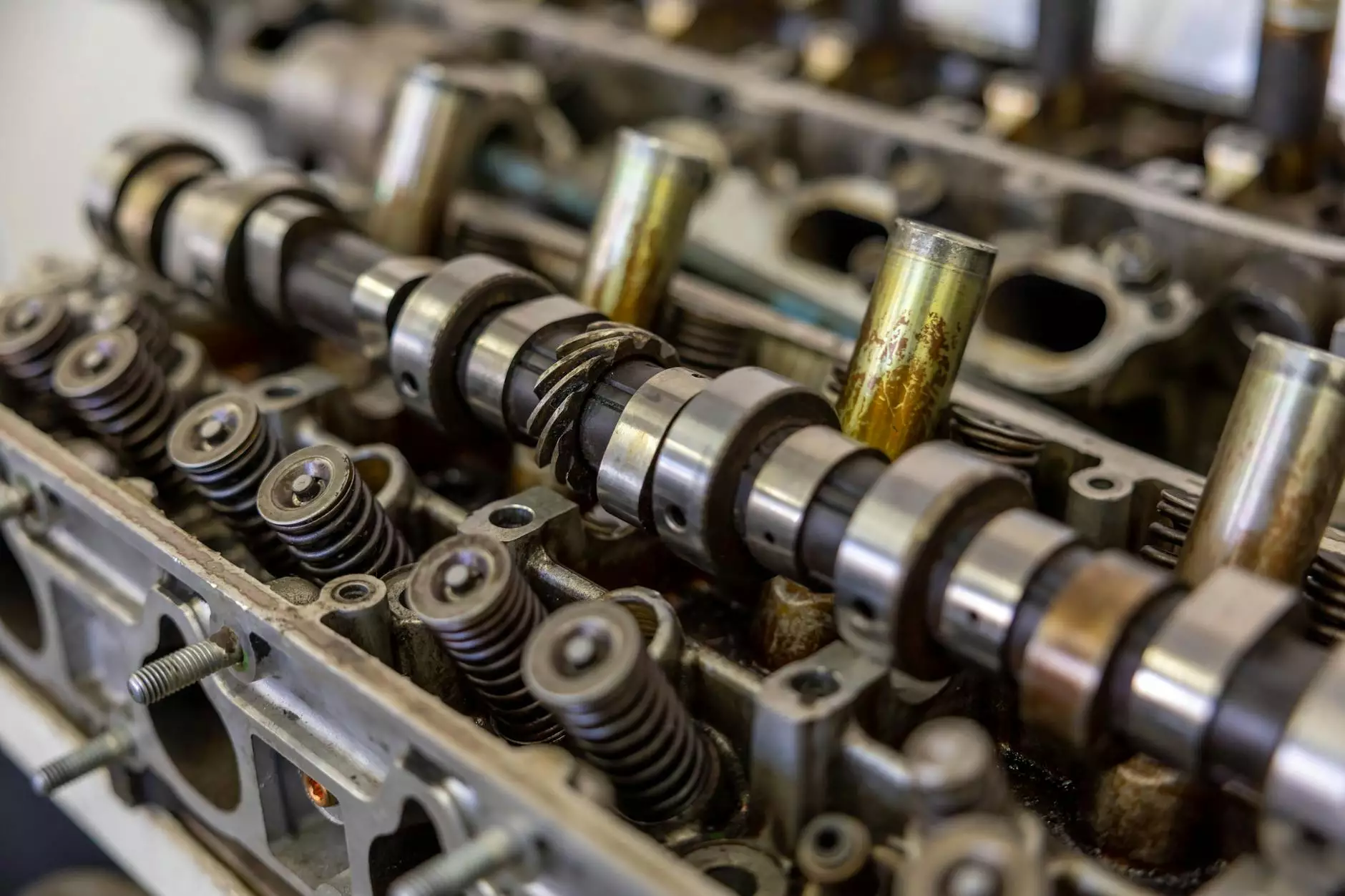

What is a Crankshaft and Its Functionality?

The crankshaft is a crucial component of an internal combustion engine. Its primary function is to convert the up-and-down (reciprocating) motion of the pistons into a rotating motion that turns the vehicle's flywheel. This transformation is essential for the engine to deliver power to the vehicle’s drivetrain. The crankshaft comprises several parts, including:

- Crank Pins: These are the points at which the connecting rods attach. The motion of the pistons pushes against these pins.

- Counterweights: These help balance the crankshaft, reducing vibrations and ensuring smooth operation.

- Main Journals: These rest in the engine block and allow the crankshaft to rotate freely.

The design and construction of the crankshaft significantly affect its performance. A well-engineered crankshaft will minimize vibration, maximize power transfer, and withstand intense mechanical stresses during operation.

How the Crankshaft Affects Engine Performance

Engine performance is influenced by the design and material composition of the crankshaft. Here are some key factors:

1. Balance and Smoothness

Proper balancing of the crankshaft minimizes vibrations, leading to smoother engine operation. An unbalanced crankshaft can result in uneven wear and tear on other engine components, ultimately leading to mechanical failures.

2. Material Selection

The materials used to manufacture crankshafts can significantly impact their strength and durability. Typically, crankshafts are made from:

- Cast Iron: Known for its durability and cost-effectiveness.

- Steel: Offers superior strength and is often used in high-performance applications.

- Alloyed Steel: Combines various metals to enhance toughness and reduce weight, ideal for high-performance engines.

3. Design Features

Many modern crankshafts incorporate design elements such as lightweighting and optimized geometries to further improve performance. Features like billet construction or forging are used to enhance strength without adding excessive weight.

The Role of Crankshafts in Diesel Engines

Diesel engines have unique requirements and challenges when it comes to crankshaft functioning. Diesel engines typically operate at higher compression ratios than gasoline engines, which necessitates a more robust design for the crankshaft. Here are a few critical points related to crankshfts in diesel engines:

1. Increased Strength Requirements

Due to the increased pressure and stress in diesel engines, crankshafts must be designed to withstand higher loads. This often requires the use of high-strength materials and specific design tweaks.

2. Importance of Lubrication

The crankshaft relies heavily on oil for lubrication to minimize friction between moving parts. Proper maintenance, including regular oil changes and using high-quality lubricants, can extend a crankshaft's lifespan significantly.

3. Impact of Engine Size

In larger diesel engines commonly found in trucks and heavy machinery, crankshafts often become larger and more complex. Manufacturers must balance strength with weight considerations to maintain fuel efficiency.

Common Issues and Maintenance Tips for Crankshafts

Maintaining the crankshaft is vital for the longevity and efficiency of any engine. Below are some common issues and maintenance tips:

1. Wear and Tear

Over time, crankshafts can suffer from wear due to friction and heat. Regular inspections can help identify signs of wear early, including:

- Scoring or scratches on the surface

- Excessive play in crank pins

- Vibration during engine operation

2. Oil Quality and Level

Maintaining the correct oil level and using high-quality oil can prevent premature wear. Always check oil levels frequently, especially before long trips or heavy usage.

3. Regular Professional Inspections

Consulting with a professional mechanic for routine inspections can catch potential crankshaft issues before they escalate. Mechanics can utilize various diagnostic tools to assess the health of the crankshaft and other engine components.

Importance of Quality Spare Parts Suppliers

When it comes to maintaining or replacing crankshafts, choosing the right spare parts suppliers is crucial. Here are some reasons why:

1. Authenticity and Quality Assurance

High-quality parts reduce the risk of failure. When sourcing a crankshaft on engine, ensure that you are purchasing from reputable suppliers like client-diesel.com that provide authentic and reliable products.

2. Warranty and Support

Reputable suppliers often offer warranties on their products, giving you peace of mind regarding your investment. In the event of a malfunction, strong customer support adds another layer of security.

3. Availability of Technical Support

The best suppliers provide not only the parts but also technical support to help you choose the right components for your needs. Many are knowledgeable about the specifications required for different engine types, ensuring you get the right fit.

Conclusion: Maximizing Engine Efficiency with Quality Crankshafts

In summary, the crankshaft on an engine is a critical component that cannot be overlooked. Understanding its function, the importance of quality materials, and regular maintenance practices ensures optimal engine performance and longevity. For professionals in the automotive industry, particularly those dealing with diesel engine parts and spare parts suppliers, knowledge of the crankshaft's workings provides a competitive edge in delivering quality service and products to customers.

Investing time and resources in understanding and maintaining crankshafts can yield significant dividends, ensuring that engines run smoothly and efficiently. Reliable suppliers like client-diesel.com can provide the necessary components to keep your engines performing at their best.